Chemical Technology

- To extreme the necessity of minimize pollutant

concentration in the effluents and reduce the

wastes production. - To suggest strategies to reduce pollutant wastes

production and their emission to the environment.

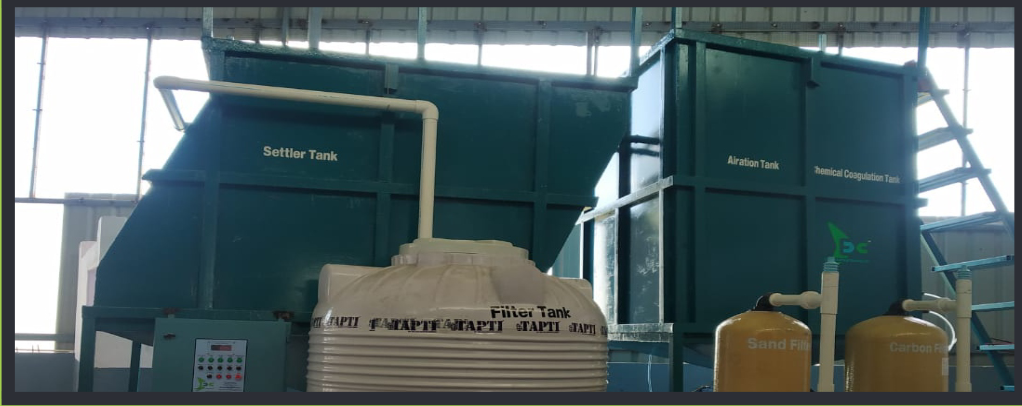

Description

Advanced wastewater treatment is defined as the processes that remove more pollutants from wastewater than the conventional treatments. This term may be applied usually as tertiary treatment, but most of their goals are to remove nitrogen, phosphorus, and suspended solids